Work Portfolio

Real results for real needs

Shop made 120mmx7in boring head, with 0.005mm increment micrometer for 0.01mm diameter change and interchangeable toolpost, 3/8"-16 threads for mounting counterweights. Specially made for long hole boring.

Project consisting of 4140 steel, 1018 steel, and 6061 aluminum parts. Used a little bit of all our capabilities, including CNC milling, lathe turning, and even designing the 6061 aluminum part from scratch to work with the client's assembly. Featuring h6 shaft fit on all critical diameters of the turned couplers and keyways.

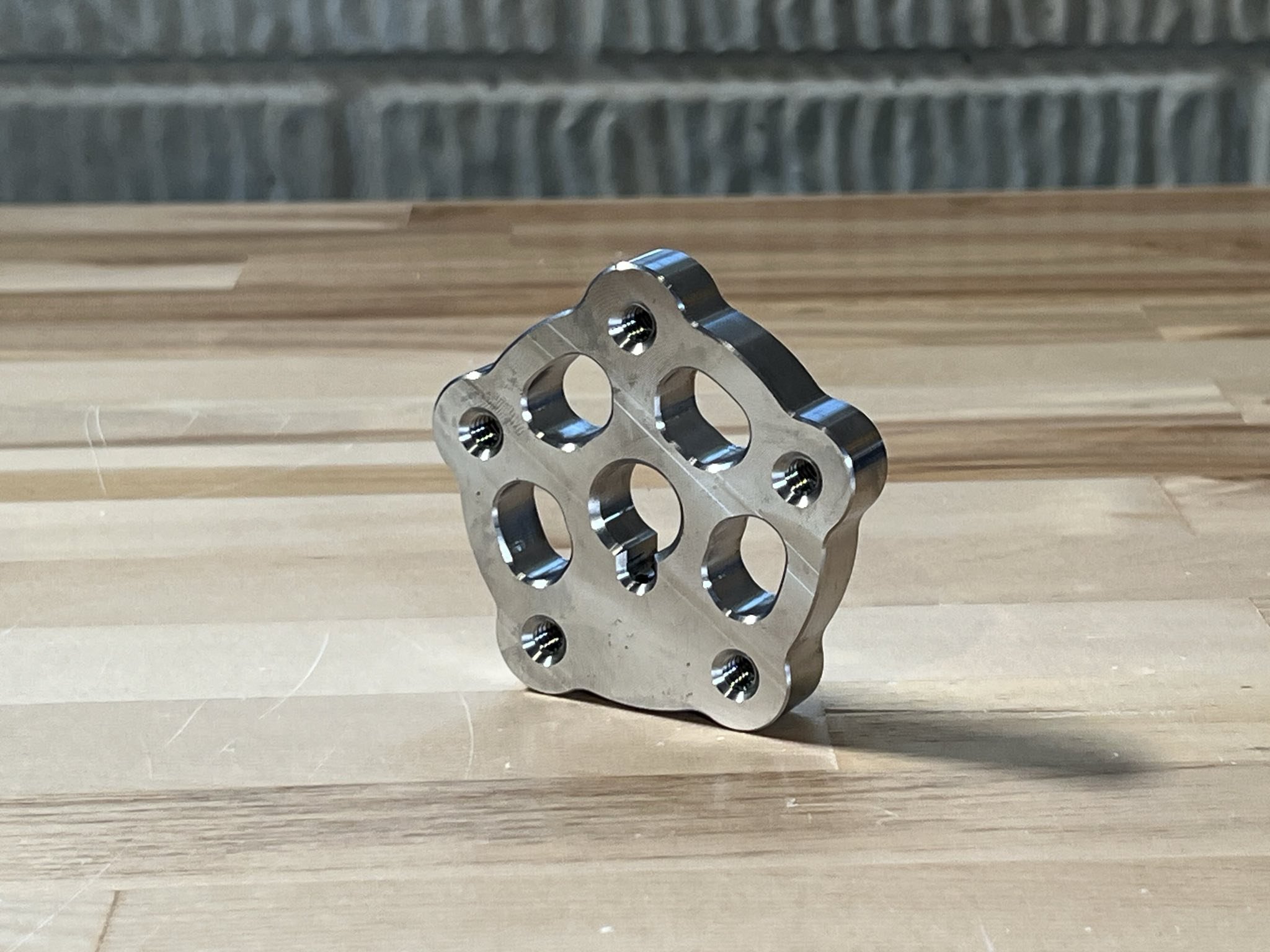

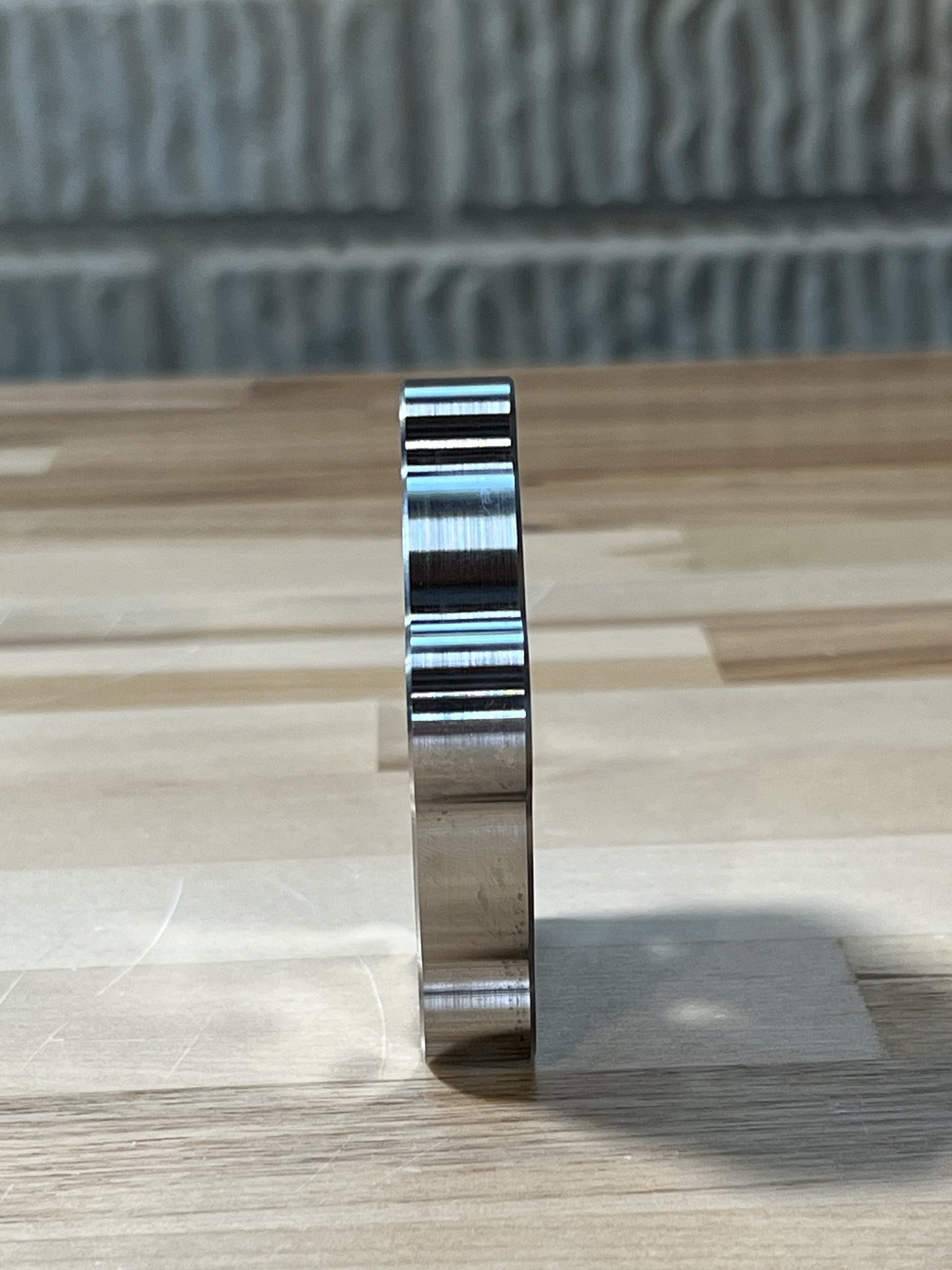

4140 Steel-CNC Milled-Prototype Car Brake Adapter-0 to +0.021mm Tolerance on 15mm Center Bore for H7/h6 Location Fit

4140 Steel-CNC Milled-Prototype Car Brake Adapter-Parallelism Within 0.001"

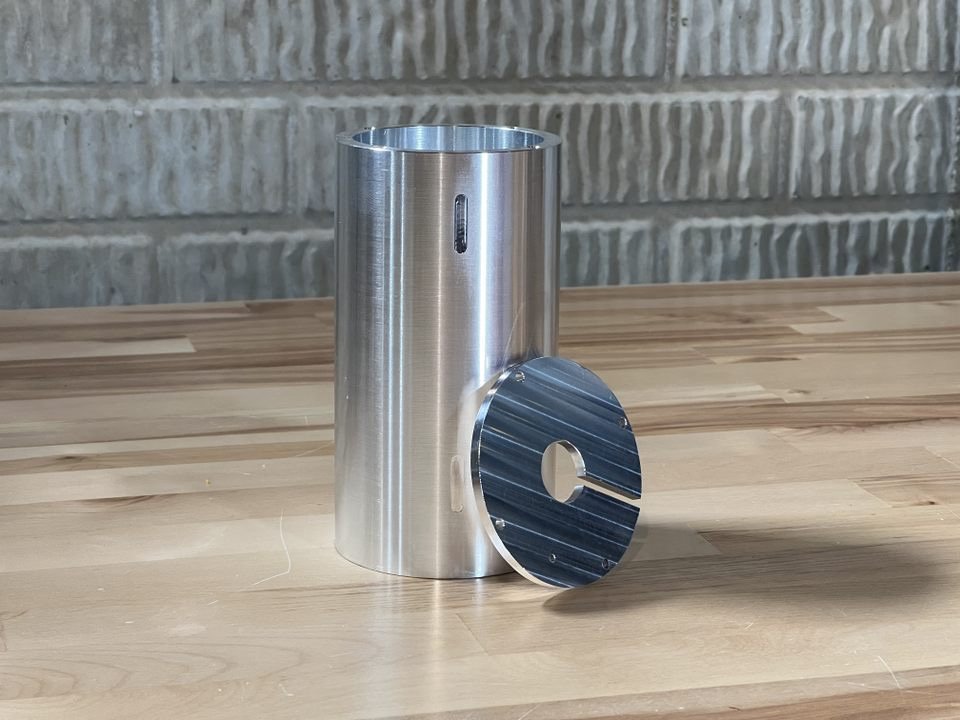

6061 Aluminum-Manual Turning+CNC Milled-Test Container with Lid

Titanium-CNC Milled-Test Part

Titanium-CNC Milled-Test Part

6061 Aluminum-CNC Milled-Threaded Standoffs

6061 Aluminum-CNC Milled-Threaded Standoffs

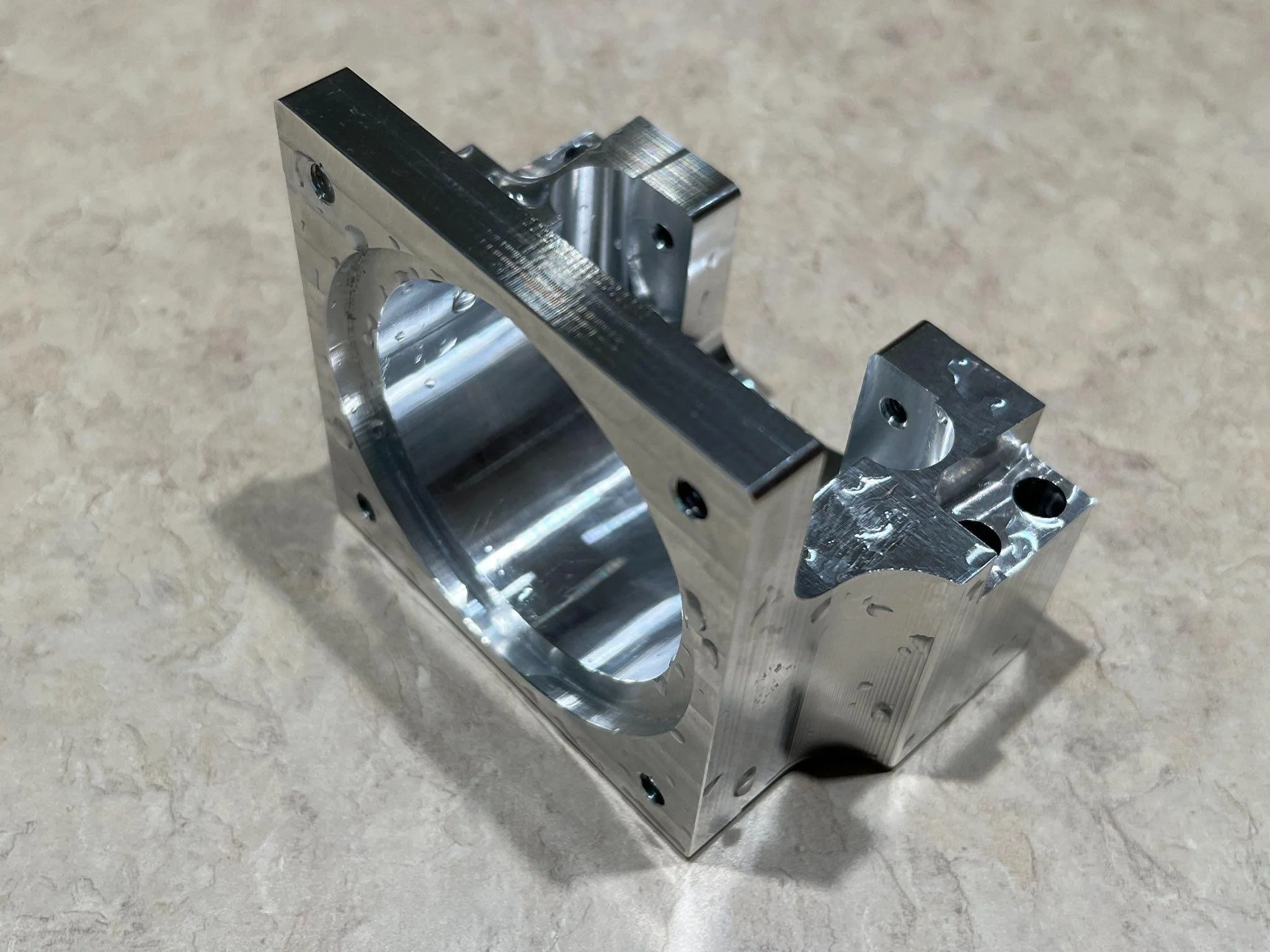

6061 Aluminum-CNC Milled-Servo Motor Housing

6061 Aluminum-CNC Milled-Servo Motor Housing

6061 Aluminum-CNC Milled-Thin Walled Bracket

MATRICS, Inc's 1st designed and built in house CNC mill-1st test cut

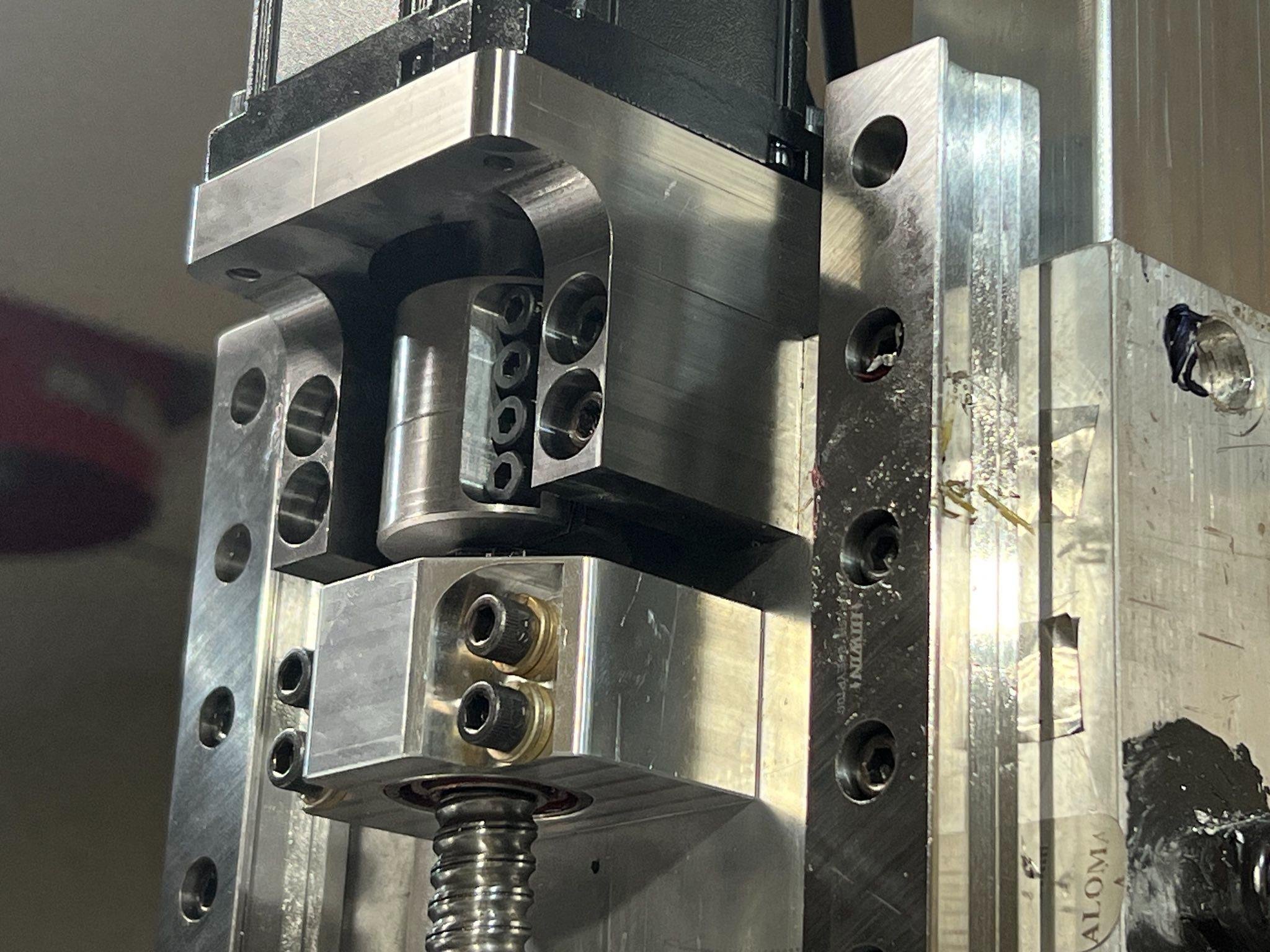

MATRICS, Inc's first designed and built in house CNC mill-Z axis servo closeup